Fiber Distribution Frame and Cabinet

Fiber Management

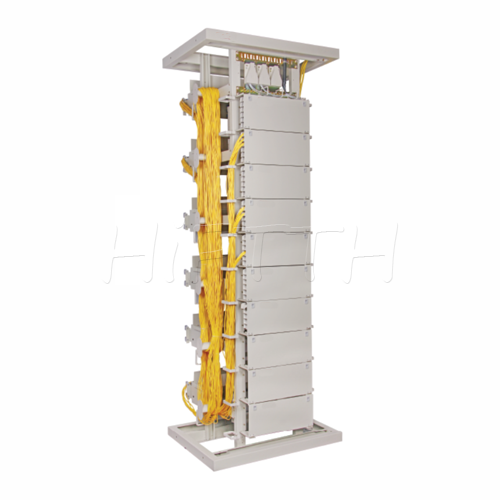

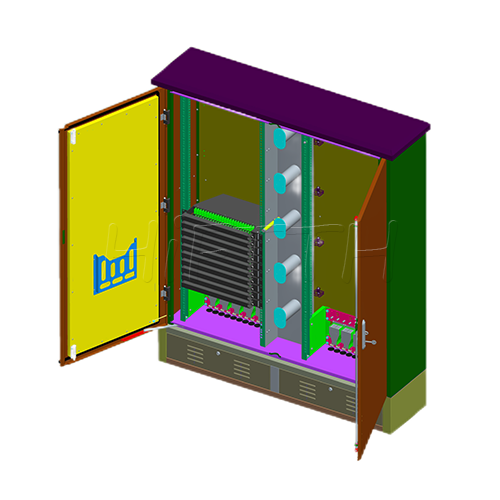

Fiber Distribution Frame Types Indoor Distribution Frame, Outdoor Distribution Cabinet

An Optical Distribution Frame (ODF) serves as a central hub in network centers for managing fiber optic connections, facilitating organized cable terminations, splices, and patches, crucial for network configuration and maintenance.

The Outdoor Distribution Cabinet, used on streets, is a robust enclosure designed for outdoor telecom equipment, offering weather resistance and efficient management of street-level fiber connections and cross-connectivity.

We do things differently

High Density

Up to 1152 cores

Cross Connect

Flexible fiber connections for efficient management

Double Front Doors

Easy access for installation and maintenance

19 inches Modular Design

For different fiber patch panels

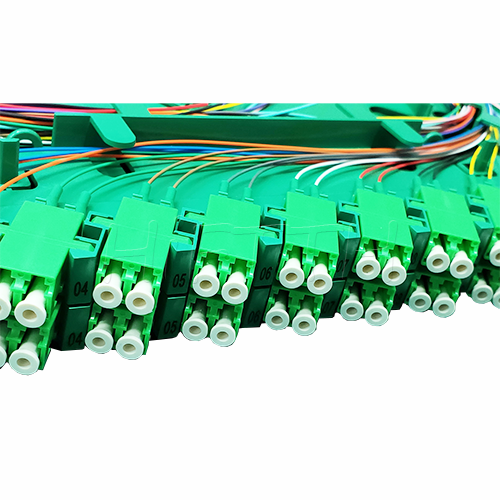

Match with multiple Fiber Optic Connectors

Compatible with SC, FC, ST, LC fiber connectors

Fiber Routing and Patching

Organized pathways for effective cable management

Fiber Patch Panel Integration

Integrated Fiber Splicing and Fiber Patching

ODM / OEM

Designs to meet specific project needs

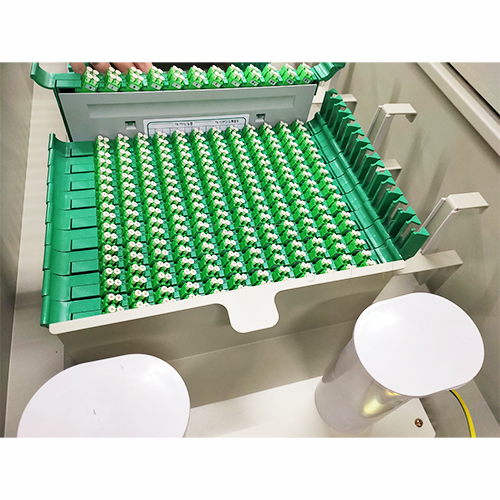

Fiber Distribution Frame Workshop

Looking for Fiber Distribution Frame for your Project?

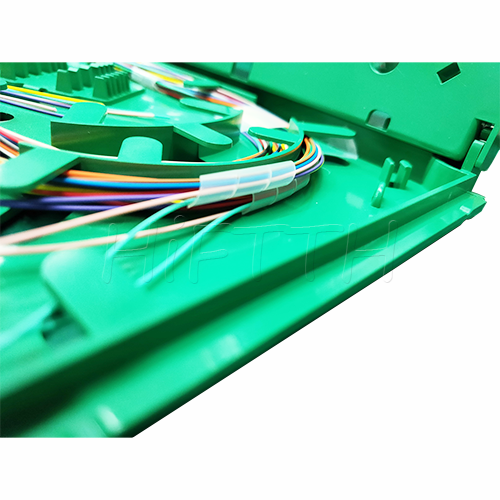

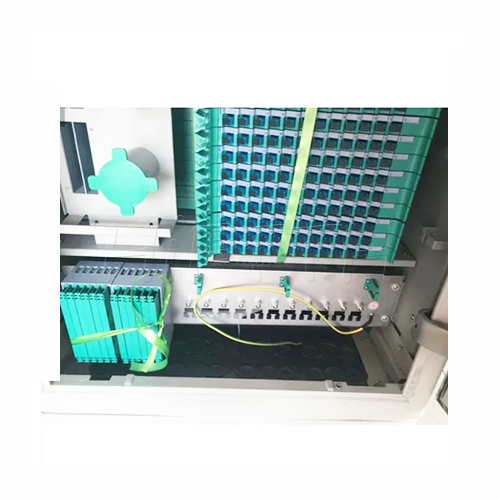

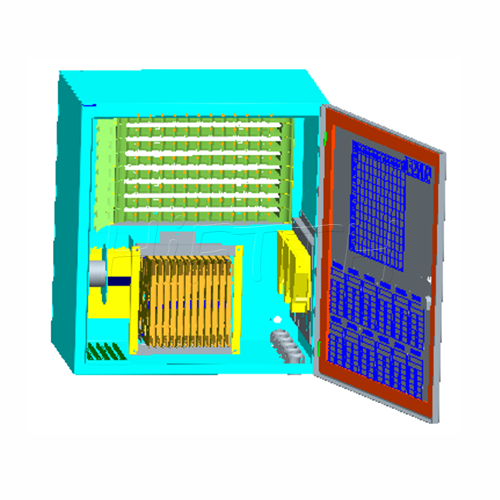

fiber distribution frame Structure

Structure Showcase

Fiber Distribution Frames and Outdoor Fiber Distribution Cabinets, essential in telecommunications, manage and safeguard fiber optic networks. They support cable organization, splicing, and connectivity, crucial for residential and commercial internet and phone services. Designed for scalability and environmental protection, they offer secure, accessible maintenance, ensuring reliable network operation in various settings.

Impact-Resistant Outer Shell

The exterior of outdoor cabinets is often made of impact-resistant materials to withstand physical shocks.

Ensures the cabinet can endure physical impacts, like accidental knocks or vandalism, protecting the delicate fibers and connections inside.

Built-In Fiber Optic Loop Storage

These units sometimes include dedicated areas for excess fiber loop storage.

Managing extra lengths of fiber, ensuring they are stored neatly and safely, which is vital for maintaining signal integrity and minimizing cable stress.

Cable Lead-In and Out Unit

Located at the bottom of the frame or cabinet, this part is where the fiber optic cables enter and leave the unit. It’s designed to hold and protect these cables.

Guide the cables in and out smoothly, preventing them from bending too much or getting damaged. It keeps the cables safe where they go into and come out of the frame or cabinet.

Modular Design

Many frames and cabinets are designed with modular components, allowing for different configurations.

This modular approach enables customization according to specific network needs and allows for easy upgrades or reconfiguration as the network evolves.

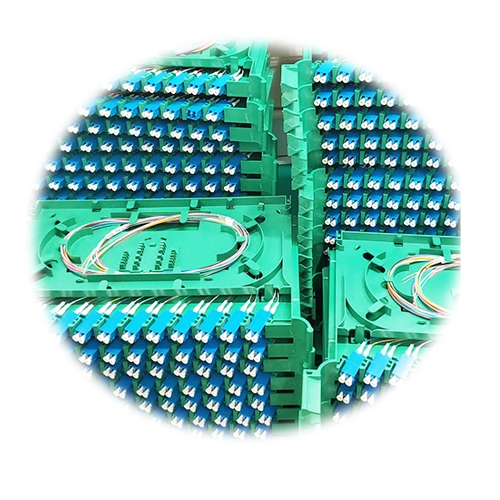

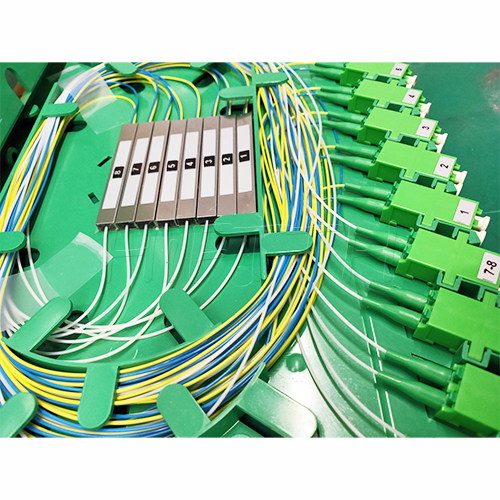

Splicing & Distribution Module

Integrated into the frame or cabinet, this module is specifically designed for both splicing and distributing fiber optic cables.

Enables the effective merging and routing of fiber connections, essential for streamlined network configuration and ensuring reliable signal distribution to various endpoints.

Integrated Fiber Optic Splitters

Cabinets in FTTH networks might include built-in optical splitters.

These splitters are essential for dividing the optical signal into multiple outputs, facilitating the distribution of services to multiple subscribers from a single fiber.

Lockable Doors

Equipped with locks on their doors to secure access and restrict unauthorized access.

Prevents unauthorized access, vandalism, or accidental damage, ensuring network safety and integrity.

Grounding System

They have special parts for grounding, like metal bars or plates, to connect them safely to the ground.

This grounding helps protect the equipment and people from electrical shocks. It also keeps the fiber optic signals clear by reducing electrical interference.

Expansion Slots

Features slots or spaces for additional modules or components.

Allows for the expansion of network capacity as demand increases, ensuring the system’s long-term viability.

Labeling System

Includes a clear and organized labeling system on the frame or cabinet.

Facilitates easy identification of cables and connections, streamlining maintenance and network management tasks.

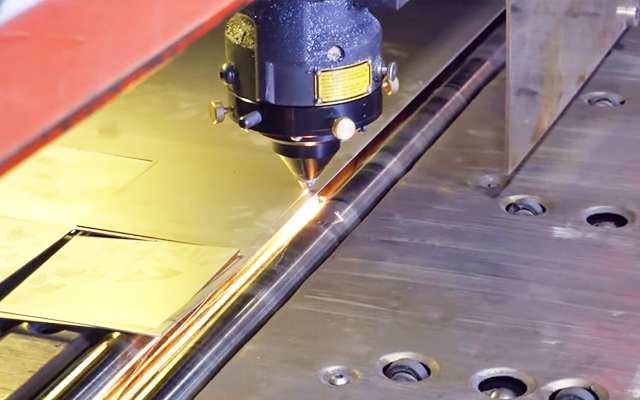

fiber distribution frame and fiber optic cabinet Workshop

Producing Process Showcase

Fiber Distribution Frame (ODF)

Engineers design the frame’s enclosure for durability and resilience, molding it from robust materials. They assemble internal components such as splice trays and panels, integrating cable management systems for efficient organization. Security features like lockable covers are incorporated. Rigorous quality checks ensure functionality and environmental protection before distribution.

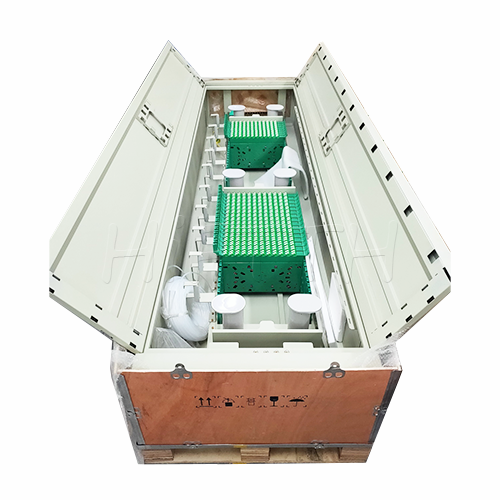

Outdoor Fiber Distribution Cabinet (ODC)

Designers prioritize weatherproofing and ruggedness, selecting materials resistant to outdoor elements. The cabinet’s enclosure is molded with durability in mind. Essential components like splice trays and splitter cassettes are assembled, along with cable management systems. Security measures, including tamper-resistant locks, are integrated. Thorough quality assurance tests validate functionality and resilience to environmental factors prior to distribution.

Cutting

Forming

Welding

Painting

Assembling

Packing

Looking for a Fiber Optic Cable for your Project?

fiber distribution frame different materials

Main structure differences

Products Showcase

Fiber Distribution Frame

The size of ODF as normal way, the heigth is 2M, 2.2M or 2.6M, width 600m, 800mm or 900mm, depth 300mm.

The structure can be single door, double-door.

The sub unit of ODF can be 19-inch or the modular tray direclty.

More be coming

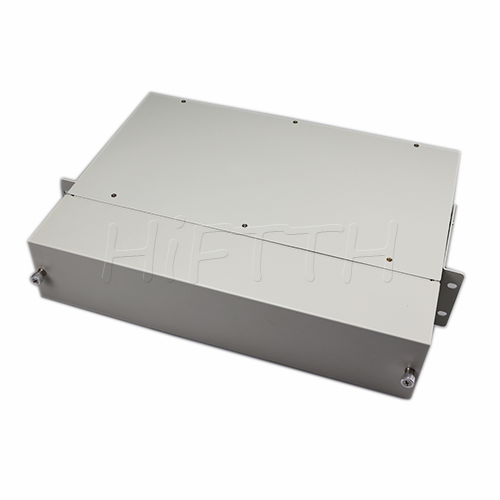

Oudoot Fiber Distribution Cabinet

It was for ourdoor street cabinet. can be 19-inch mounted or the termination&distribution tray flexible mounted.

As normal The capacity from 96 fibers to 1152 fibers.

The raw material can be SMC or Metal sheet.

More be coming

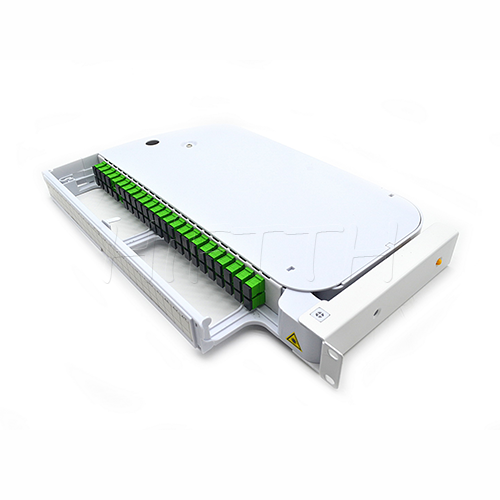

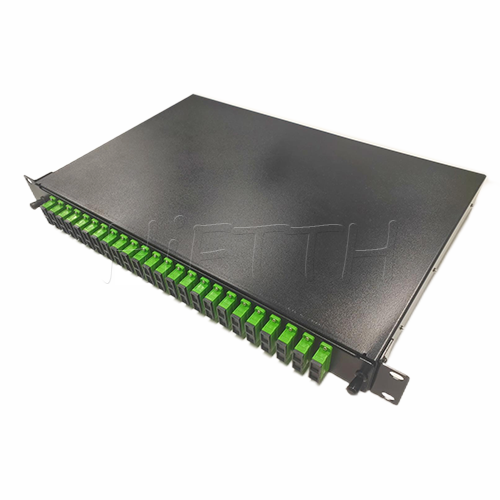

Fiber Patch Panel

19 inch standared mounted, the capacity from 12F to 144F. 1U to 6U.

Hight density Panel can be 2U for 144 fibers.

More be coming

You Ask

We Answer

Need help?

FAQs

What types of fiber distribution frames are available?

Wall-mounted and rack-mounted fiber distribution frames are available.

How many fiber ports can the frame accommodate?

It can accommodate from 144 to 1152 ports, depending on the model.

Is this frame compatible with both SC and LC connectors?

Yes, it is not only compatible with both SC and LC connectors, FC connector, ST connector and E2000 connector all be ok.

Does it support both single-mode and multi-mode fibers?

Yes, it supports both single-mode and multi-mode fibers. but for FTTH application mostly on siglemode.

How about the height size of the standard ODF?

Typically, it is 2m, 2.2m, or 2.6m. and customized is available.

Does the frame include built-in cable management?

Yes, it includes built-in cable management features.

What is the recommended indoor environment for installation?

A clean, dry, and temperature-controlled indoor environment is recommended.

What mounting options are available for the Fiber Outdoor Cabinet?

It can be installed on a concrete base or mounted on a pole, offering flexibility for various installation environments.

What power supply requirements does the cabinet have?

It does not require a power supply as it is passive, but there are options to include power if needed for active components.

Is the cabinet available in different sizes to meet specific project needs?

Yes, the cabinet is available in multiple sizes to accommodate different capacity requirements for various projects.

What are the key features to look for when purchasing feeder cables?

Yes, installation instructions are provided. it also include the fiber splicing protection sleeve, bare fiber protection tube for fiber cable splicing.

Can the frame be customized for special project requirements?

Yes, customization options are available upon request.

Is the fiber distribution frame expandable?

Yes, certain models allow expansion by adding modules. and it can as required to add the expansion frame beside.

What type of material is used for the frame body?

The frame is typically made from high-quality steel with a powder-coated finish.

How does the frame prevent dust and moisture?

The frame is equipped with a protective cover to keep out dust and moisture.

What safety features does the frame include for fiber protection?

The frame includes bend radius protection and secure cable management to prevent fiber damage.

Is there a grounding option for the frame?

Yes, grounding options are provided to ensure safety.

What is the estimated lead time for delivery?

The lead time is typically 2-4 weeks, depending on the order quantity.

How is the cable slack managed inside the frame?

The frame includes spools and guides to manage cable slack effectively.

Is it compliant with international standards for fiber optic installations?

Yes, it is compliant with international standards such as ISO/IEC and TIA/EIA.

Related Products

Your ODN network product assistant