Joint Closure

Fiber Management

Joint Closure Dome joint closure, Horizontal joint closure

Fiber optic closures are protective enclosures used in various network types, including transport, metropolitan, FTTx, and PON. They feature IP68 protection and accommodate direct splicing of fibers or to fiber optic splitters. Installation can be in cable chambers, underground, or mounted on poles or walls. Key considerations for selection include aerial vs. buried placement, in-line vs. butt, port counts, and cable diameter. These closures protect optical fiber splices and connectors from different cables, such as feeder, branch, drop, ribbon, loose tube, and microcables. Constructed with weather-resistant shells and fiber managers, they can be installed Man-hole, in aerial settings, or wall-mounted.

We do things differently

Durable Plastic Materials

PC+ABS, PC/ABS/PP

Variety Mounting Application

Wall mounting, Aerial mounting and pole mounting application.

High Density

Up to 576 fibers

High Rate Water and Dust Protection

Meet with IP68

Nice Designing

Dome type and Horizontal type

Variety Splice Tray

12 fibers, 24 fibers, 36 fibers or 48 fibers

Cable Entry

Heat shrink or Mechanical seals

Variety Fiber Cable matching

From 6mm to 20mm

FOSC Joint Closure supplier

Looking for FOSC Joint Closure for your Project?

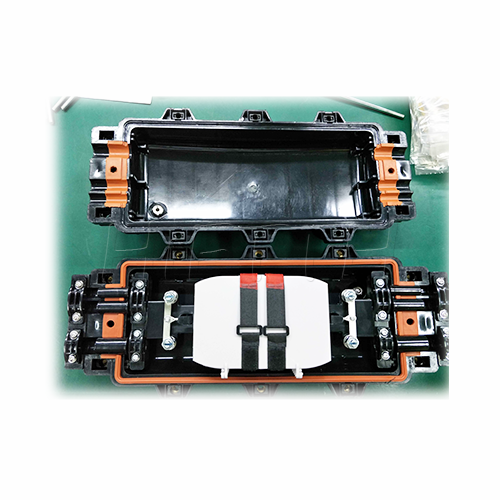

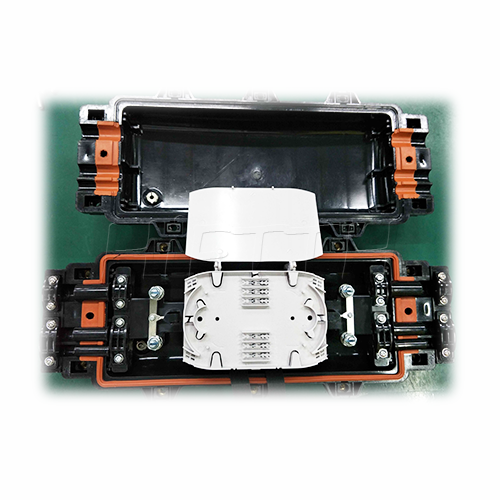

FOSC Joint Closure Structure

Structure Showcase

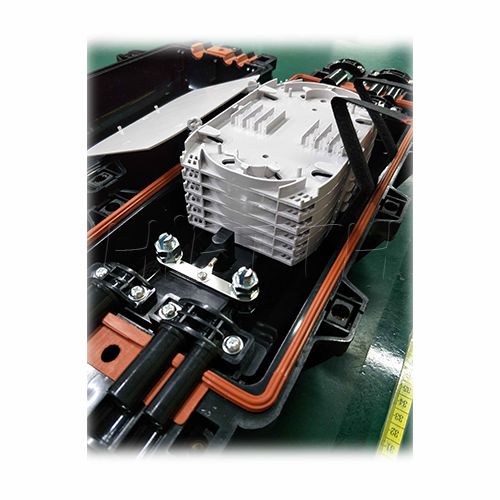

Exterior Shell

Typically made from high-strength materials like reinforced plastic or metal, designed to endure harsh environmental conditions including UV exposure, temperature extremes, and moisture.

Provides a robust barrier against external elements, ensuring the long-term integrity and performance of internal fiber connections.

Internal Fiber Holding Trays

Trays or compartments within the closure for securely holding and organizing spliced fibers.

Facilitates precise and protected splicing of fibers, ensuring effective alignment and connection while preventing entanglement and stress on the fibers.

Bend Radius Control

Internal design features such as guides or channels specifically shaped to ensure that fibers are laid out with proper bend radius.

Prevents excessive bending of the optical fibers, which is critical for maintaining signal integrity and preventing fiber damage, especially important in environments with frequent adjustments or in high-density splicing situations.

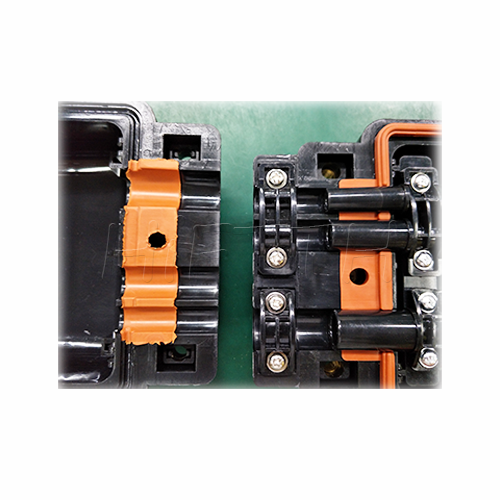

Sealing Mechanism

Robust seals, typically made of rubber or similar materials, that are integrated into the closure.

Ensures a watertight and dustproof environment for the delicate fiber connections, crucial for maintaining signal integrity.

Cable Ports

Entry and exit points engineered to accommodate various types and sizes of fiber optic cables.

Provides structured and secure entry and exit pathways for optical cables, maintaining proper bend radius and protecting cables from strain.

Lockable Cover

A lockable lid or access panel, often requiring tools or keys for opening..

Prevents unauthorized access and tampering with the internal fiber connections, maintaining network security.

Clamping and Anchoring Mechanism

Seals and gaskets around openings and covers that prevent water ingress.

Ensures that cables are firmly anchored, reducing strain and risk of disconnection or damage, particularly in outdoor or high-movement environments.

Pressure Equalization Valve

A small, specialized valve integrated into the closure’s body.

This valve helps to equalize internal and external pressure, particularly important in preventing condensation inside the closure and in maintaining seal integrity during temperature and altitude changes. It’s especially useful in outdoor or varying environmental conditions, ensuring long-term protection of the fiber connections.

Loose Tube Storage Area

A designated space within the closure specifically for accommodating excess lengths of loose tube fibers.

This area allows for the storage of extra lengths of fiber, providing redundancy and flexibility for future network adjustments or repairs. It ensures that there is sufficient slack for re-routing or re-splicing fibers without the need for additional cabling, thereby enhancing the closure’s adaptability and serviceability over time.

Mounting Provisions

Exterior brackets or points for secure installation.

Allows for stable and accessible mounting on walls, poles, or other structures.

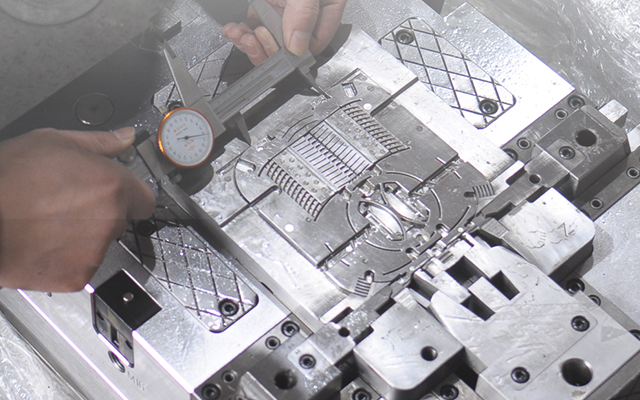

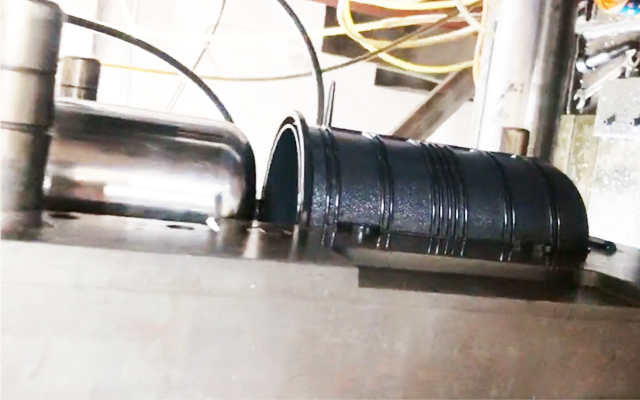

FOSC Joint Closure Workshop

Producing Process Showcase

Raw Material Preparation

Design and Mold Manufacturing

Molding Process

Injection Molding of Inline Closure

Injection Molding of Dome Closure

Related components assmbly

Packing after 100% quliaty control

Looking for FOSC Joint Closure for your Project?

FOSC Joint Closure different materials

Main structure differences

FOSC Joint Closure Products

Dome Closure

The Dome type FOSC Joint Closure is popular for wall mounted and Pole mounted.

It was made from plastic, such as PC, PC+ABS or PP.

The Cable entrance meet with mid-span and sealling method is heatshrinking tube or mechnical sealing.

The capacity from 24F to 576F.

More be coming

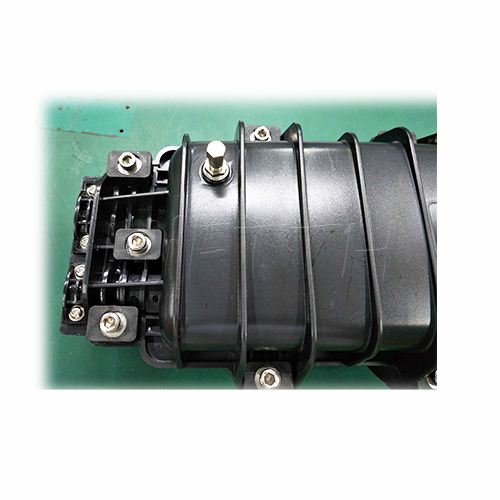

Inline Closure / Horizontal Closure

The Horizontal type FOSC Joint Closure is popular for Manhold and Buried mounted.

It was made from plastic, such as PC, PC+ABS or PP.

The Cable entrance at the both side by rubber ring with mechical sealing.

The capacity from 24F to 576F.

More be coming

You Ask

We Answer

Need help?

FAQs

Does the product come with all necessary mounting accessories?

Yes, the mounteing accessories are include in the package, but have to mentioned whicy type mounting way you need.

What are the types of FOSC Joint Closures available?

There are Dome Closures (vertical type) and Inline Closures (horizontal type) available.

What is the difference between Dome Closure and Inline Closure?

Dome Closure is a vertical enclosure, ideal for aerial and pole applications, while Inline Closure is horizontal, suitable for underground or duct installations.

How many splice trays can a FOSC Joint Closure accommodate?

A FOSC Joint Closure can typically accommodate 2 to 12 splice trays, depending on the model.

What is the capacity of each splice tray in the OFC Joint Enclosure?

Each splice tray can hold up to 24 fibers, depending on the specific model.

Can a Dome Closure be used for underground applications?

Yes, a Dome Closure can be used for both aerial and underground applications.

How is cable entry handled in an Inline Closure?

- Inline Closures have multiple cable entry ports, typically 4-8, to allow for branching or mid-span access.

What precautions should I take during cable splicing?

Always use a clean environment, ensure precise alignment, and avoid contamination to maintain low insertion loss.

What materials are used for the FOSC Joint Closure?

The closure is made of high-quality, UV-resistant plastic that provides durability in outdoor environments. such PC+ABS, PC/ABS/PP

Can multiple cables enter the same port?

Yes, some models allow multiple small cables to share a single port using branch gaskets.

What is the expected lifespan of the FOSC Joint Closure?

The closure has an expected lifespan of 20+ years with proper installation.

Can the closure handle both armored and non-armored cables?

Yes, it is compatible with both types of cables.

What tools are needed for installation?

Basic tools include a splicing machine, fiber cleaver, and fiber protection accessories.

What is the maximum fiber capacity of this closure?

It can handle up to 576 fibers, depending on the splice tray configuration.

What type of sealing method is used in Dome Closures?

Dome Closures use a mechanical or heat shrink sealing method to ensure a watertight seal.

Are splice trays included with the FOSC Joint Closure?

Yes, splice trays are included and can be added or removed based on the required capacity.

Can the OFC Joint Enclosure be re-opened for maintenance?

Yes, it is designed to be re-enterable for maintenance and future expansion without compromising its sealing performance.

How many cables can be connected to a typical Inline Closure?

It can connect up to 4-8 cables, depending on the number of entry ports and configuration.

Is the FOSC Joint Closure resistant to temperature changes?

Yes, it is designed to withstand a wide range of temperatures, from -40°C to +65°C.

What are the typical applications for Dome and Inline Closures?

Dome Closures are used in aerial and manhole installations, while Inline Closures are ideal for direct burial or duct applications.

Is grounding required for the OFC Joint Enclosure?

Yes, grounding is required, especially for installations where metallic components are present.

Related Products

Your ODN network product assistant