What Seems Expensive Is Often Saving You Money

“This pre-terminated product is too expensive—we can’t afford it.”

That’s a common first reaction from many small ISPs and contractors when they see pre-terminated cables or fully assembled fiber distribution systems.

Yes, if you only look at the unit price, these pre-terminated systems, plug-and-play connectors, and pre-configured boxes do cost more than traditional components.

But if we zoom out to the full FTTH project cycle, the real project cost isn’t just materials—it’s in installation, rework, delays, and coordination. In this chapter, we’ll walk through the hidden costs that often go unnoticed but silently erode your project’s margin.

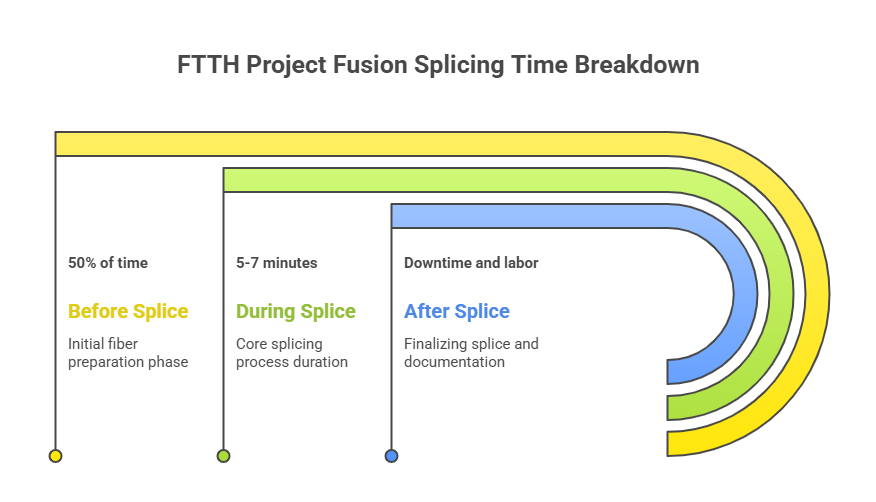

1. The Hidden Cost of Fusion Splicing

Every FTTH project involves fusion splicing. Many assume it’s simple: a splicing machine + technician = a few minutes per joint. But let’s break down what really happens:

Before the splice:

Cut, strip, and clean the fiber

Slide heat shrink tubing

Mount fibers into the splice tray, label each one

Prepare environment: power on the machine, wait for it to heat up

These steps are often overlooked but can take up more than 50% of on-site working time.

During the splice:

Each splice takes 5–7 minutes on average

A typical home requires 2–4 splice points

Unskilled workers or poor site conditions double the time

After the splice:

Coil slack fiber, fix into tray, label, test for loss

Close up the box and document the result

Cost-wise:

Each splice point adds around $6 USD in labor and downtime

Add consumables (heat shrink, protection sleeves) and tool depreciation

Realistically, **each household costs approximately $20–27 USD more due to these invisible splice tasks

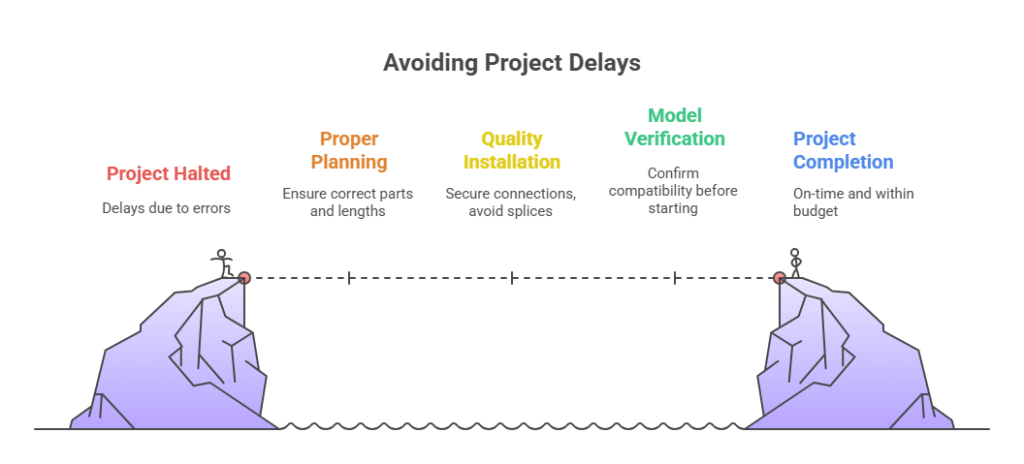

2. Rework: The Most Underestimated Cost Driver

Real-world examples we’ve seen:

Patch cords too short—can’t reach terminals

Splice failure leads to high loss—job must be redone

Mismatched models—project halted while waiting for new materials

What’s worse, one small mistake causes a domino effect:

Labor team waits an extra day = full-day pay wasted

Emergency reshipping = express logistics fees

Delayed delivery = client dissatisfaction, possible loss of future work

Many contractors only realize after closing their books: rework alone ate 20% or more of their margin.

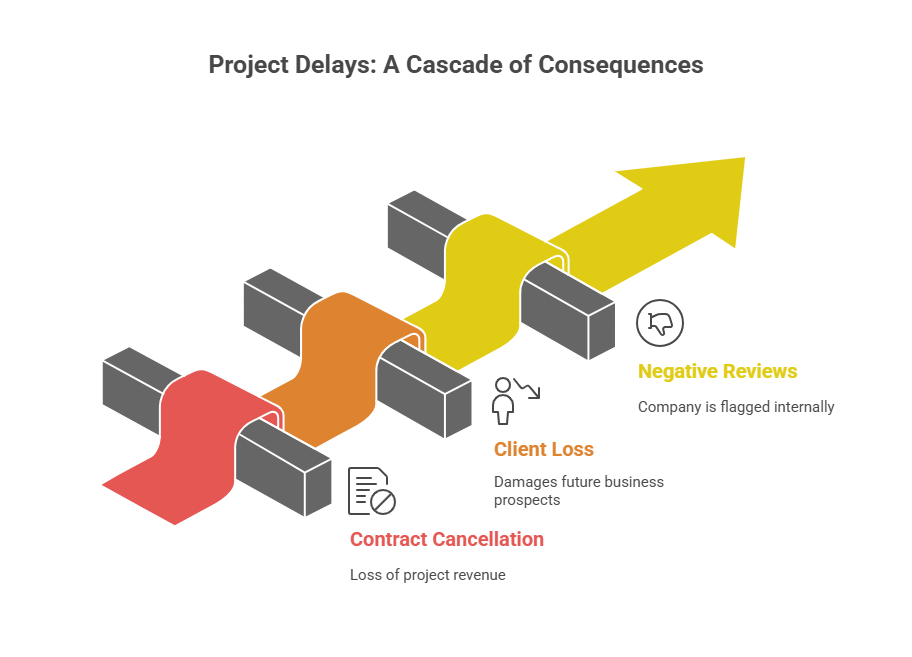

3. The Price of Missed Deadlines: Trust Takes a Hit

On-time delivery is make-or-break for smaller ISPs and contractors.

Let’s say you promised delivery by the 1st. But due to late materials or on-site confusion, everything gets pushed to the 5th. Even if quality is fine, you’ve now been marked as “unreliable.”

Worse consequences:

Government or operator-led projects will deduct payment—or worse, cancel the contract

New clients who experience delays the first time won’t come back

Your company may be flagged as the problem supplier during internal postmortem reviews

A minor delay can cost you an entire region’s business.

4. Why Pre-Terminated Solution Actually Cut Costs

Let’s do a side-by-side breakdown:

| Cost Element | Traditional Deployment | Pre-Terminated + Pre-Configured |

| Material Unit Price | Lower (buy cables & boxes separately) | Higher (customized & pre-assembled) |

| Labor Costs | High (splicing + configuration + testing) | Low (plug-in + mount) |

| Tools & Consumables | Must rent or buy, high usage | Barely needed or none at all |

| Installation Time | ~60 minutes per home | ~20–30 minutes per home |

| Rework/Error Rate | High (manual work + mismatched parts) | Low (factory-tested, complete kits) |

| Future Maintenance/Upgrade | Complex (track records, re-splice) | Easy (standard ports, plug replacement) |

✅ Bottom Line:

While unit prices are higher, overall project cost drops by 20–40%

Faster timelines, more stable delivery, and happier clients

Ideal for fast-moving, resource-constrained project teams

Clients Care About Total Project Cost—Not Just Unit Prices

At first, many contractors hesitate due to price. But once they’ve actually used pre-terminated systems, the feedback changes:

“It’s not about saving a few bucks—it’s about delivering the project on time.”

“No splicing, no rework—our schedule never slipped.”

“I’d rather pay a bit more up front than chase down materials in the field.”

For smaller ISPs looking to build long-term trust and quickly respond to client needs, control and reliability in delivery matter far more than chasing the lowest possible product price.

Chapter One: “The market is cooling down”—but where exactly is it cold?

Chapter Two: What Project Owners Are Really Facing

Chapter Three: The Evolution of FTTH Deployment

Chapter Four: Deployment Cases Breakdown

Follow us to get notified when the next article is out, or contact us ([email protected]) to learn more about how we support fast-moving FTTH projects with plug-and-play solutions.