Fast Connector

Fiber Connectivity

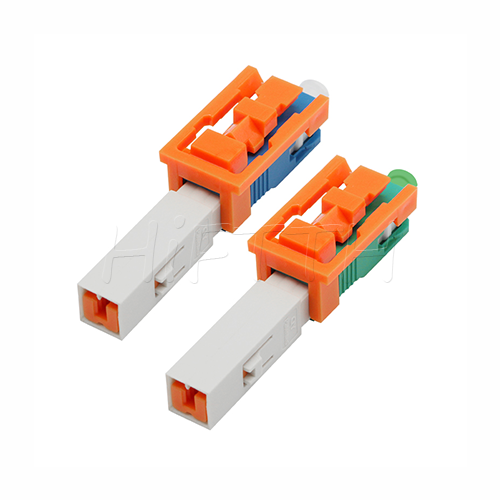

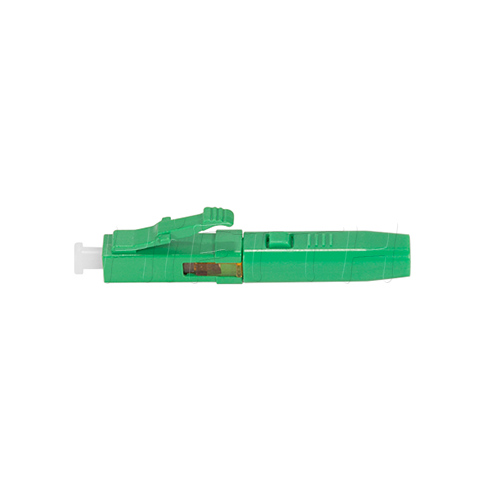

Fast Connector SC, LC, FC

Fiber Optic Fast Connectors, also known as “Field-installable Connectors” or “Fiber Optic Quick Connector” are a type of fiber optic connector designed for easy and rapid field termination of fibers. They are widely used in fiber optic networks for applications where traditional splicing is not practical or where quick repairs and installations are needed. It is a valuable tool in modern fiber optic networks, offering a quick and effective solution for fiber terminations in various environments.

We do things differently

Easy Installation

Tool-free, quick, and simple to install

Connector Types

SC, LC, FC options available

High Compatibility

Compatible with 2.0mm, 3.0mm, and 0.9mm cables

Reusable Design and Dust Protection

Can be reassembled multiple times

Precision Alignment

Ensures low insertion loss and high return loss

No Epoxy Required

Eliminates curing time for faster deployment

Flexible Order Quantities

Small and bulk orders both supported

Free Sample Availability

Free samples provided for testing and evaluation

Features

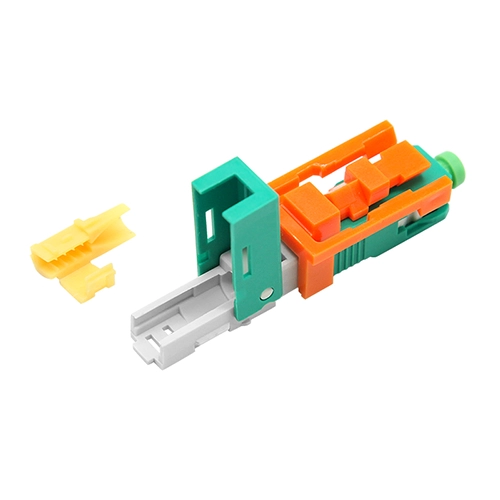

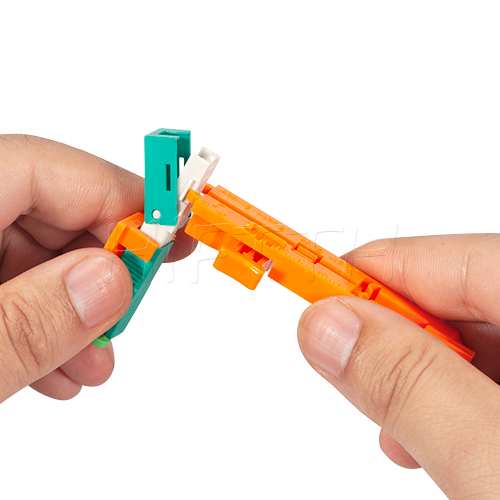

- 【Easy Installation】-Designed for easy, tool-less, or minimal-tool installation, often using a simple cleave-and-connect method.

- 【No Need for Fusion Splicing】-Unlike traditional fiber connectors that may require expensive and complex splicing equipment, fast connectors can often be installed with minimal tools, sometimes just a fiber cleaver and a simple assembly tool.

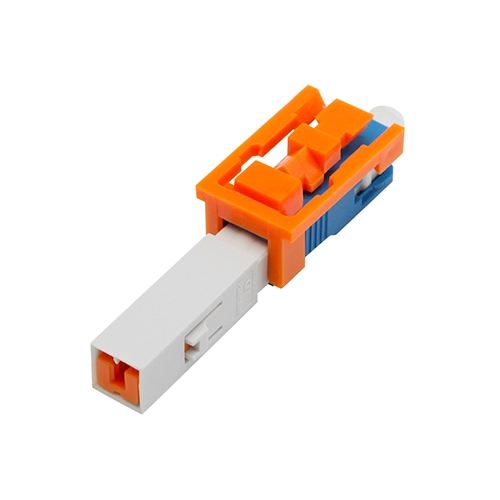

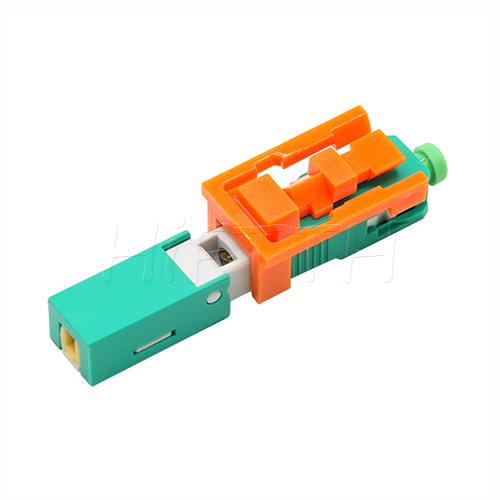

- 【Pre-Polished Ferrule】-Typically come with a pre-polished ferrule and a mechanical splice inside the connector body. This design simplifies the installation process and helps maintain good optical quality.

- 【Versatility】 -For various applications, including FTTH (Fiber to the Home), data centers, telecommunication networks, and cable TV networks.

- 【Types and Compatibility】 -Compatible with standard single-mode and multimode fibers. They are available in common connector types like SC, LC, ST, and FC.

- 【Mechanical Splice Inside】 - Hold a mechanical splice that aligns the fiber core with the pre-polished stub. and for minimizing insertion loss.

- 【Field Assembly】-Can be used to make connections right at the installation site, useful for on-the-spot repairs or last-minute changes in network layout.

- 【Index Matching Gel】 -to minimize signal loss at the connection point.

- 【Reusable】-Designed to be reusable, allowing for adjustments or re-terminations if necessary

Applications

Their ease of use and minimal tool requirements make them ideal for field installations or emergency repairs, where traditional splicing methods might be too time-consuming or require specialized equipment.

Fast connectors are widely used in FTTH projects for quick and efficient connections at the subscriber’s premises or in outdoor environments.

In data centers, where quick reconfiguration of network layouts might be necessary, fast connectors provide a flexible and speedy solution for modifying fiber optic connections.

They are used for quick repairs or expansions in telecom networks, especially in situations where rapid restoration of service is essential.

For events, demonstrations, or situations where temporary fiber optic connections are needed, fast connectors are a practical choice due to their easy installation and removal.

Advantages vs Dis.

Advantages

Speed – Quick to install, saving time and labor costs.

Convenience – No need for expensive splicing equipment, ideal for emergency repairs or where splicing is not feasible.

Flexibility – Can be used in a variety of settings and for different fiber types.

Disadvantages

Performance – While very convenient, they may not always match the low loss and high reliability of factory-terminated connectors or fusion spliced connections.

Cost per Connector – Generally, they are more expensive than standard connectors, but this can be offset by the reduced labor and equipment costs.

How They Work

Preparation: The fiber optic cable is prepared by stripping the jacket, removing the buffer coating, and then cleaving the fiber to create a flat, clean end.

Insertion: The prepared fiber is inserted into the fast connector, which typically contains a pre-polished ferrule and a mechanical splice inside.

Securing the Fiber: The connector often uses a mechanical crimp or a similar method to secure the fiber in place and align it precisely with the pre-polished ferrule.

Index Matching Gel: Many fast connectors use an index matching gel inside the mechanical splice area to help minimize signal loss at the connection point.

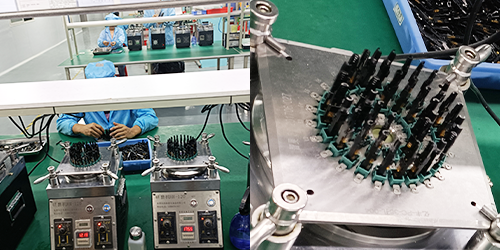

How They Production

Component Fabrication

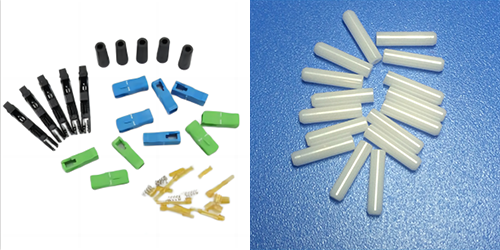

- The process begins with the fabrication of the various components of the fast connector. This typically includes the connector body, ferrule (a small, cylindrical component that holds the fiber), spring, and other mechanical parts.

- These components are often made from materials like plastic (for the body) and ceramic or metal (for the ferrule).

Assembly of Connector Parts

- The individual parts of the connector are assembled. This involves inserting the ferrule into the connector body and adding a spring to ensure proper fiber tension.

- Some fast connectors also include a pre-installed stub fiber inside the ferrule, which is factory-polished for optimal performance.

Pre-Polishing Ferrules

- For connectors with pre-installed stub fibers, the ferrule end is pre-polished. This step is crucial as it ensures a smooth, flat surface that is necessary for low signal loss when the connector is used.

Testing and Inspection

- Checking the polish quality of the ferrule and ensuring the connectors meet specific performance standards, such as insertion loss and return loss parameters.

Quality Control Checks & Packaging

- Inspecting the physical dimensions, ensuring proper assembly.

- Once they pass quality control, the connectors are packaged.

Fast Connector supplier

Looking for Fast Connector for your Project?

Products Shows

What we supply

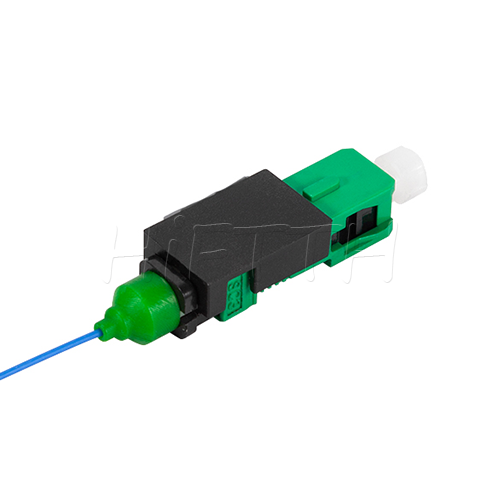

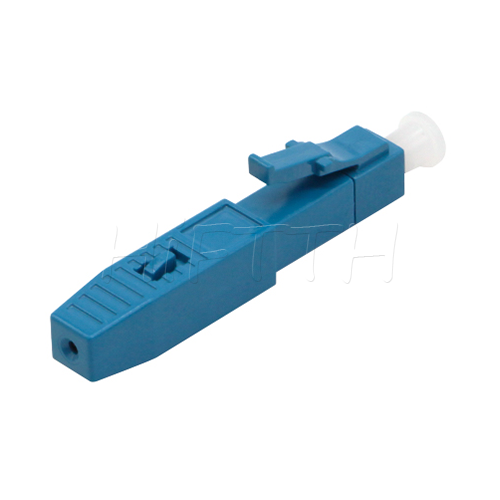

SC Fast Connector

More be coming

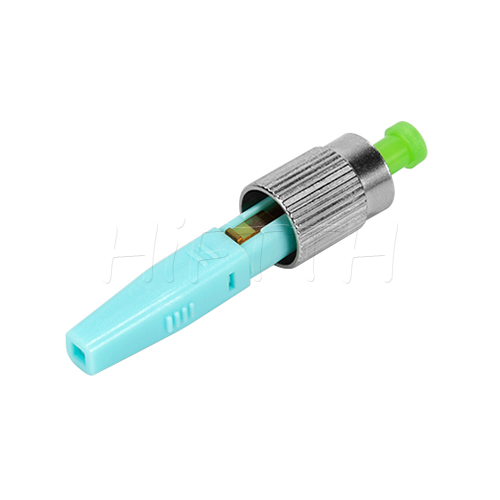

FC Fast Connector

More be coming

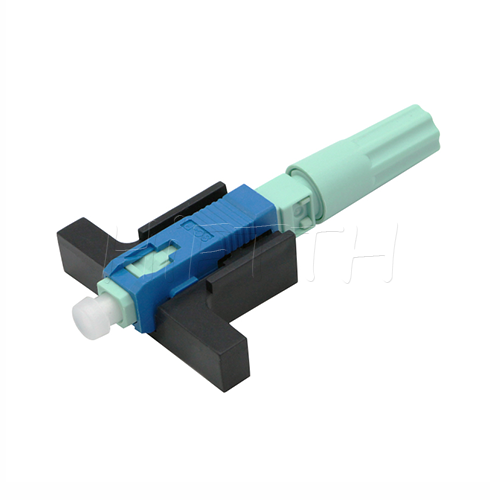

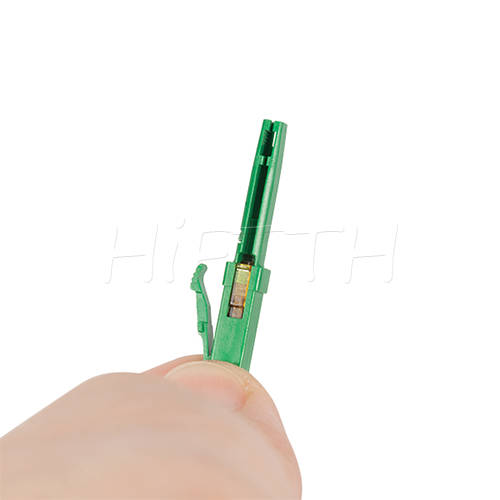

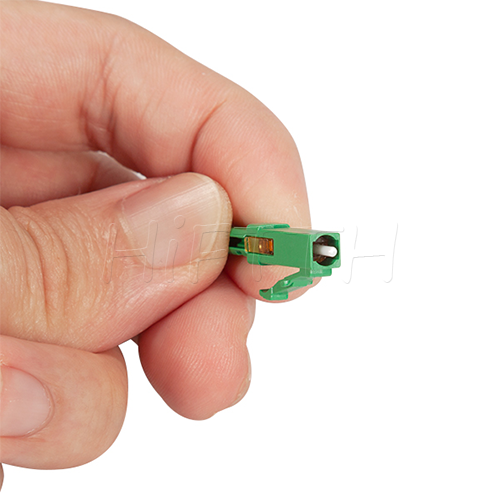

LC Fast Connector

More be coming

You Ask

We Answer

Need help?

FAQs

What are the main types of fiber optic fast connectors?

he most common types include SC, LC, FC, and ST connectors, supporting both single-mode and multi-mode fibers.

What is a fiber optic fast connector?

A fast connector is a pre-polished, tool-less connector designed for quick and reliable fiber terminations in the field.

What are the key advantages of using fast connectors?

Fast connectors provide quick installation, eliminate the need for epoxy or polishing, and reduce labor costs.

How do I choose the right connector type for my project?

Select a connector type based on your application, fiber type (single-mode or multi-mode), and equipment compatibility.

Are fiber optic fast connectors reusable?

Most fast connectors are designed for single-use, ensuring reliable performance, but some reusable options are available.

What is the typical insertion loss of a fiber optic fast connector?

Insertion loss ranges from 0.2 dB to 0.5 dB, depending on the connector type and quality.

What is the return loss specification for fast connectors?

Return loss is typically ≥55 dB for single-mode connectors and ≥30 dB for multi-mode connectors.

What tools are required to install a fiber optic fast connector?

Basic tools include a fiber cleaver, stripper, and alcohol wipes. No additional polishing or adhesives are needed.

How long does it take to terminate a fiber with a fast connector?

Termination typically takes 2-3 minutes per connector with proper tools and training.

Are fast connectors compatible with all fiber types?

Most fast connectors support 2.0mm, 3.0mm cables, and 2×3.0mm ftth drop cables Verify compatibility before purchase.

What are the packaging options for fast connectors?

Fast connectors are available in bulk packaging or as part of installation kits.

Do you provide installation training or manuals?

Yes, we offer detailed installation manuals and training videos to assist users.

What factors should I consider before placing an order?

Specify the connector type, fiber type, cable diameter, and operating environment for accurate selection.

What is the MOQ for fiber optic fast connectors?

We offer flexible MOQs, supporting both small and bulk orders.

What type of sealing method is used in Dome Closures?

Yes, we provide samples to help you evaluate the product’s performance.

How do I ensure a secure connection during installation?

Ensure the fiber is properly cleaved and clean before insertion, and follow the connector’s alignment instructions.

What is the lead time for ordering fast connectors?

Standard lead times range from 5-7 workdays, depending on order volume.

How do I test the performance of a terminated fast connector?

Use an optical power meter and light source to measure insertion loss and continuity.

What should I do if a fast connector fails during installation?

Verify fiber cleaving quality and cleanliness. If the issue persists, replace the connector.

Are there fast connectors for specific applications, like FTTH?

Yes, fast connectors designed for FTTH projects are available, optimized for field installations.

What after-sales support do you offer for fast connectors?

We provide technical support, troubleshooting, and replacement services for any defective products.

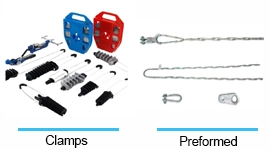

Related Products

One-stop Fiber Product Supplier