Fiber Optic Cable Cables

Fiber Cable

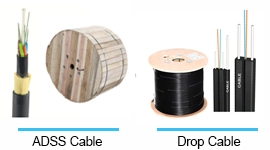

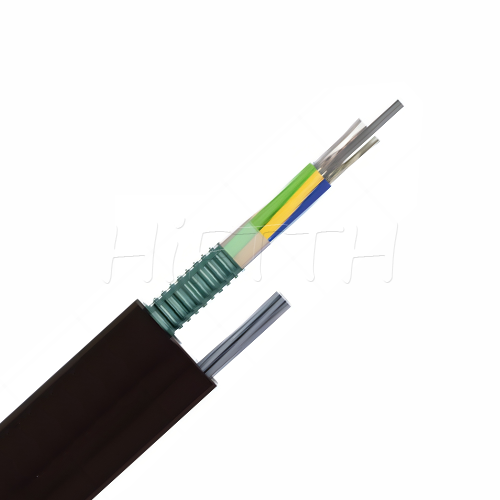

Fiber Optic Cable Cables Type Duct, Aerial, Self-supporting aerial

HiFTTH’s Fiber Optic Cable cables provide exceptional solutions for FTTH networks. Our cables are designed to ensure reliable signal transmission from central offices to end-user access points, with features like high fiber count, advanced UV resistance, and water blocking for durability in harsh conditions.

Whether installed in ducts or aerial, HiFTTH’s cables are built for versatility and long-term performance. With added rodent protection and easy installation, our cables help minimize maintenance needs and reduce operational challenges. Trust HiFTTH for high-quality fiber optic solutions that connect urban, suburban, and rural areas with efficiency and reliability.

We do things differently

S-Z stranded or Central tube structure

Up to 288 fibers

Metallic armored or Unarmored

Good grush resistance

Steel wire or FRP Strength member

Good Mechanical performance

Water-blocking construction

Moisture-proof and prevents water penetration

Tube filling compound

ensure fiber protection

PE sheath materials

UV resistant, anti-roddent

Color Strip customized

Easy identification during maintenance

Packing length

Usually 4km per durm

Fiber Optic Cable Suppliers

Looking for best Fiber Optic Cable cables for your Project?

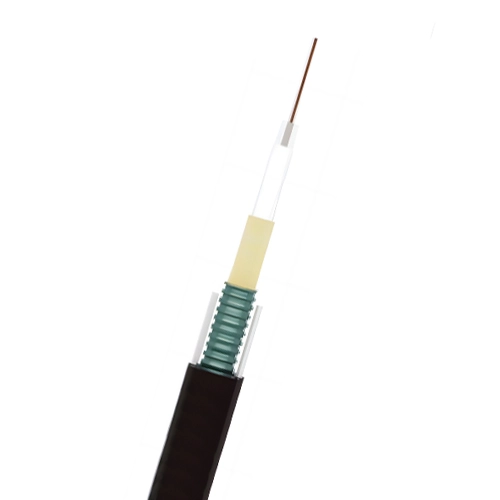

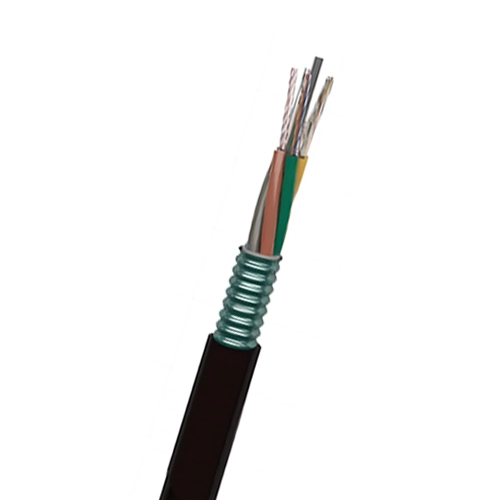

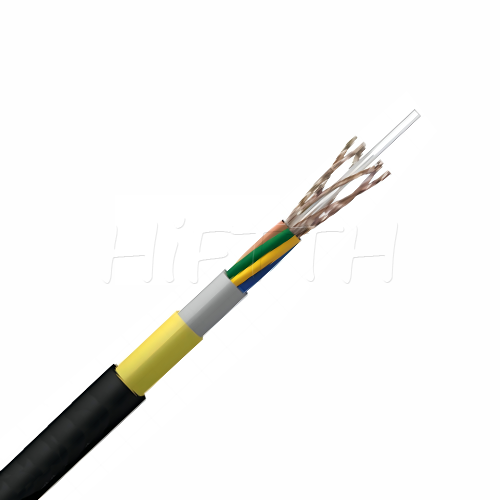

Fiber Optic Cable Cables Structure

Structure Showcase

Fiber Core

Multiple cores within the cable.

Transmits optical signals efficiently.

Loose Tube

A thin, protective tubing around the fiber core.

Provides extra protection for the core, allowing for expansion and contraction with temperature changes.

Moisture Barrier

A wrap or gel around the core.

Prevents moisture and gas intrusion.

Reinforcement Element

Metal core, often steel or glass fiber.

Provides mechanical strength.

Fiber Core

Multiple cores within the cable.

Transmits optical signals efficiently.

Filling Compound

A thick, gel-like substance surrounding the reinforcement.

Adds additional protection and insulation to the cable.

Armor Layer

Metal or other durable materials.

Protects from physical damage; suitable for various installations.

Outer Sheath

Resistant chemical material.

Shields against environmental stress and damage.

Rip Code

A cord placed under the outer sheath.

Facilitates easy removal of the outer sheath during installation.

Color Strip

Colored marking on the outer sheath.

Provides cable identification and differentiation.

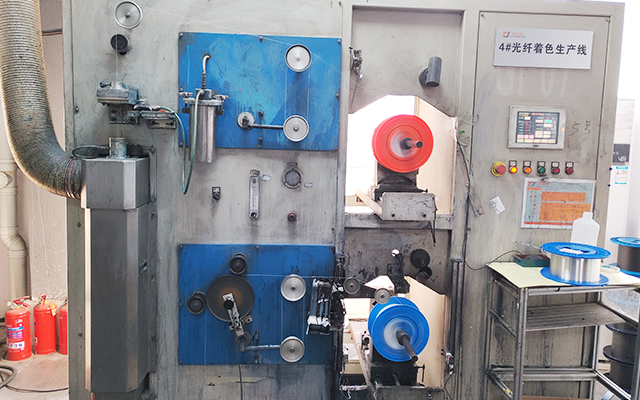

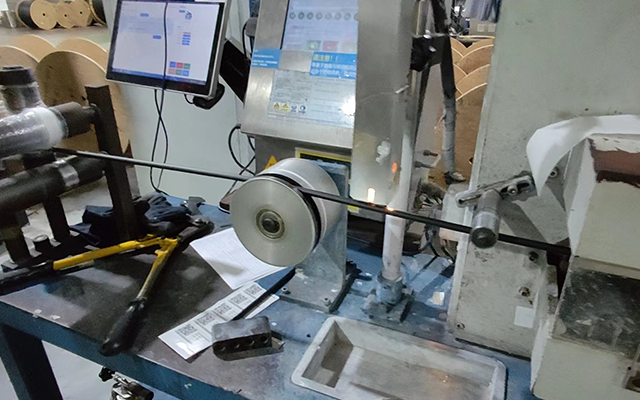

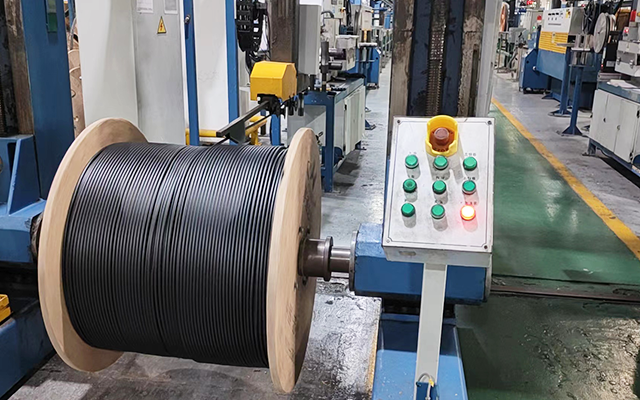

Fiber Optic Cable Cables Workshop

Producing Process Showcase

Fiber Coating

To be Loose Tube

Tube Stranded

Filling Compound Wrapping

Armour Layer

Cable Jacket

Cable Marker

Rolling onto the drum

Looking for a Fiber Optic Cable for your Project?

Fiber Optic Cable cables different materials

Main structure differences

Fiber Optic Cable Cables Delivery

Fiber Optic Cable on Container Loading

Except the fiber optic cable best price, try the best to full filled the container is our responsible too. for save the shipping cost for our client.

Fiber Optic Cable Cables

Outdoor Fiber Optic Cable

HiFTTH’s Outdoor Fiber Optic Cable offers reliable connectivity with 100% quality assurance, competitive pricing, and free samples available. Built for durability in all outdoor environments.

Duct & Aerial Fiber Optic Cable

More be coming

Self-supporting aerial Fiber Optic Cable

More be coming

Buried & Duct Fiber Optic Cable

More be coming

Special Application Fiber Optic Cable

More be coming

Indoor Fiber Optic Cable

HiFTTH’s Indoor Fiber Optic Cable is designed for reliable, high-speed connectivity indoors, ideal for vertical or horizontal cabling in building corridors. With 100% quality assurance, competitive pricing, and free samples available.

More be coming

Need help?

FAQs

How do I choose the right feeder cable for my FTTH project?

Consider application such as installation environment (duct, aerial, underground), fiber count requirements, and network capacity needs.

What should I consider when installing feeder cables underground

Ensure proper trench depth, use water-blocking features, and follow local installation standards to prevent damage.

How can I protect cables from rodents during installation?

Use cables with built-in rodent protection, or add conduit for additional security in high-risk areas.

What are the common challenges in aerial cable installation?

Wind load, pole distance, and tension are key factors. Ensure proper tensioning and use brackets for stability.

How can I reduce signal loss during installation?

Minimize bends and kinks in the cable and use quality connectors with proper splicing techniques.

How do I determine the appropriate fiber count for my network?

Assess current capacity requirements and plan for future scalability to avoid frequent upgrades.

What precautions should I take during cable splicing?

Always use a clean environment, ensure precise alignment, and avoid contamination to maintain low insertion loss.

How do I ensure long-term durability of installed cables?

Proper installation, use of protective conduits, and regular maintenance checks can significantly extend cable life.

What is the best way to handle excess feeder cable during installation?

Avoid tight coiling; use proper cable storage methods to prevent stress on the fibers.

How do I ensure proper tension during aerial installation?

Use tension meters and follow recommended values to avoid damaging the cable or sagging.

What is the recommended bending radius for fiber optic cables?

Typically, it is 15 times the cable diameter for static and 20 times for dynamic bends to avoid fiber stress.

How do I prevent connector contamination during installation?

Always keep connectors covered, clean them before use, and handle them with care.

What certifications should I look for when buying optical cables?

Look for compliance with standards such as ITU-T, IEC, and RoHS for quality assurance.

How can I reduce installation time for distribution cables?

Use pre-terminated cables, proper planning, and experienced installers to minimize time.

What are the benefits of using HiFTTH's feeder and distribution cables?

Our cables offer superior durability, optimized performance for FTTH networks, and feature a design focused on easy installation and reliable operation.

What are the key features to look for when purchasing feeder cables?

High tensile strength, UV resistance, water blocking, and flexibility for different installation scenarios.

How can I identify water ingress in underground installations?

Use water-blocked cables and regularly inspect joints to prevent moisture from entering the cable.

How do I select between armored and non-armored fiber optic cables?

Armored cables are ideal for high-risk environments with physical threats, while non-armored is suitable for low-risk areas.

What connector types are recommended for FTTH feeder and distribution cables?

SC and LC connectors are commonly used; choose based on network design and equipment compatibility.

How can I avoid unnecessary cable splicing during installation?

Measure accurately, use pre-terminated cables where possible, and plan routes effectively.

What testing should be performed after cable installation?

Perform OTDR testing to check for signal integrity and verify proper splicing.

How do I prevent cable damage during duct installation?

Use proper lubricants, avoid sharp bends, and pull gently to prevent excess strain on the cable.

What type of environment is best suited for aerial fiber optic cable?

Aerial feeder cable is best suited for areas with stable pole infrastructure and minimal wind or storm exposure.

How can I ensure proper grounding for optical cables?

Use grounding kits as per the manufacturer’s instructions to protect against electrical faults.

What factors impact the cost of optical cable?

Fiber count, cable type (armored or non-armored), installation method, and protective features all influence cost.

How do I handle fiber cable during extremely cold weather?

Avoid bending as the cable becomes less flexible; use a controlled environment for installation when possible.

What maintenance is required after installation?

Regular inspections of joints, connections, and cable integrity are essential to prevent issues.

Can feeder cables be reused if they need to be relocated?

Yes, but care must be taken during removal, and they should be inspected for any damage before reinstallation.

How do I choose between duct and direct burial for optical cable installation?

Duct installation offers better protection, while direct burial is faster and cost-effective for short-term projects.

How can I identify issues in fiber optic cable performance?

Regular signal testing and visual inspections of joints and splices can help detect issues early.

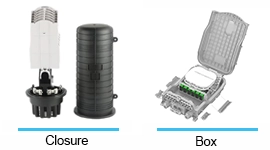

Related Products

Your ODN network product assistant