Optical Fiber Splitter

Fiber Connectivity

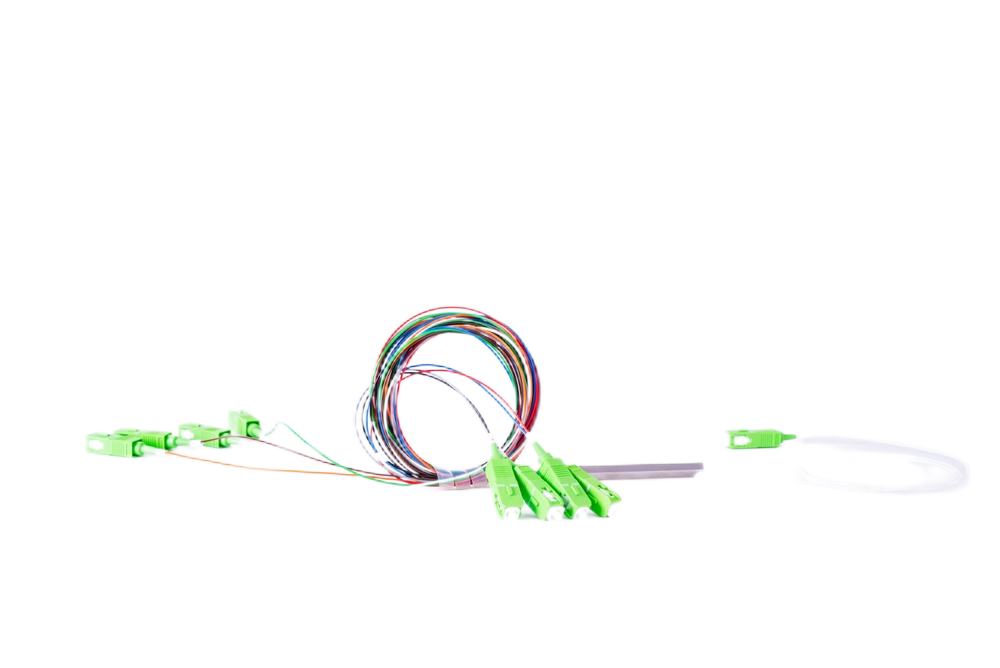

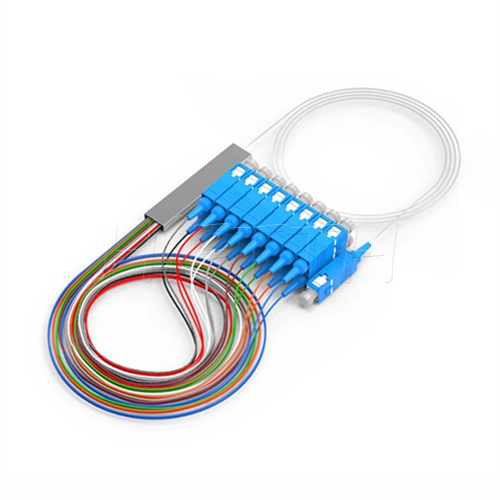

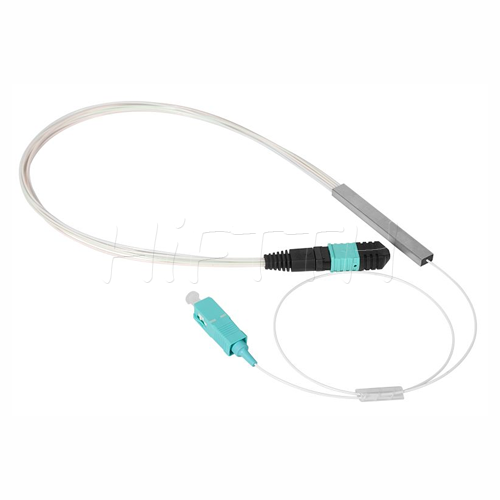

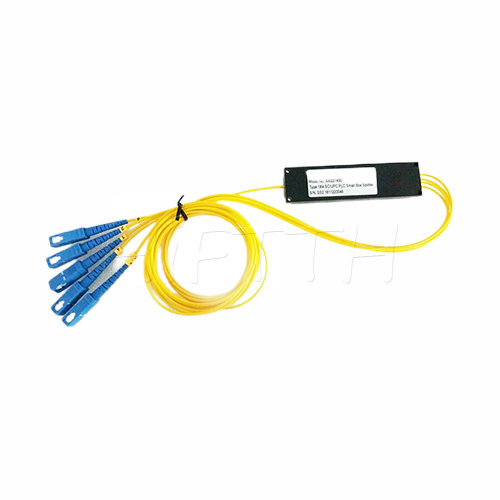

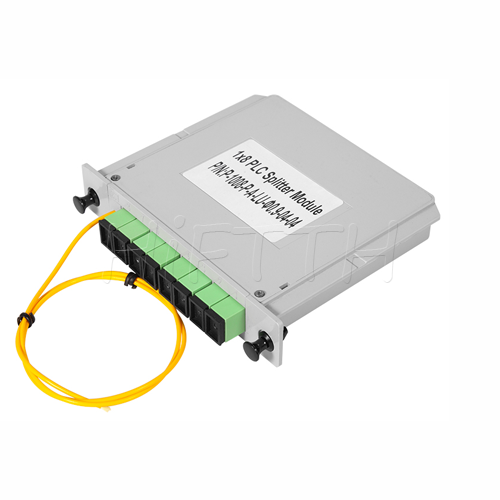

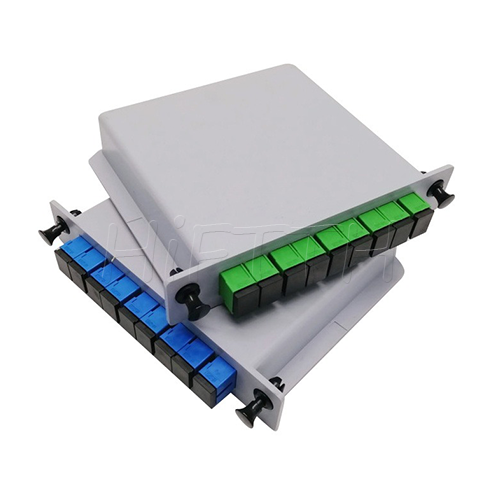

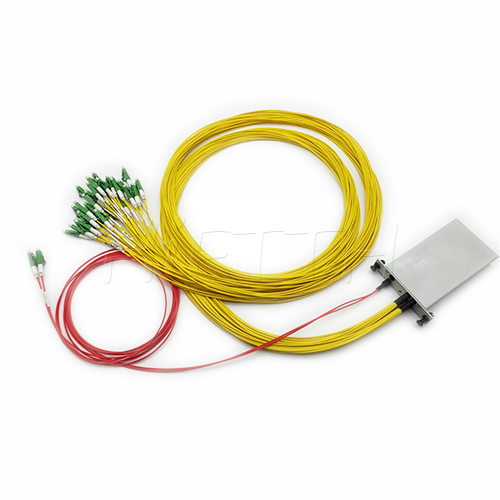

Optical Fiber Splitter Bare, Mini, Cassettes, LGX

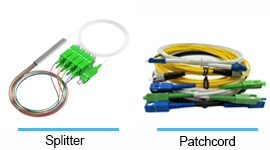

PLC (Planar Lightwave Circuit) splitters, which are a type of optical power management device widely used in fiber optic networks, particularly in FTTH (Fiber to the Home) and PON (Passive Optical Network) systems. It is an essential component in modern fiber optic networks, providing an efficient and reliable means of distributing optical signals across multiple paths without requiring power.

We do things differently

Splitter Types

Bare, Mini, Cassettes, LGX types

Splitting Ratios

Options include 1x2, 1x4, 1x8, up to 1x128 or 2x2, 2x4, 2x8, up to 2x128.

High Optical Performance

Low insertion loss and high uniformity

Connector Options and Dust Protection

SC, LC, FC, ST, and more

Custom Configuration

Splitter ports and lengths tailored to needs

Wide Wavelength Range

Supports 1260nm to 1650nm wavelengths

Flexible Order Quantities

Stable performance in harsh conditions

Free Sample Availability

Free samples provided for testing and evaluation

Features

- 【Uniform Splitting】-They provide equal signal splitting, which is crucial for balanced data transmission in networks.

- 【Low Insertion Loss】-PLC splitters are designed to have low insertion loss, meaning they minimize the loss of signal strength during splitting.

- 【High Return Loss】-High return loss indicates that very little signal is reflected back to the source, which is important for maintaining the quality and consistency of the signal.

- 【Compact Size】-They are typically compact and can be easily integrated into various types of fiber optic distribution boxes or enclosures.

- 【Wide Wavelength Range】 - operate efficiently over a broad range of wavelengths, typically covering standard telecommunications wavelengths such as 1310 nm, 1490 nm, and 1550 nm. This makes them versatile for different types of optical signals.

- 【High Reliability】-They are highly reliable, with good thermal stability, ensuring consistent performance over a wide temperature range.

- 【Good Directivity】-They offer good directivity, which helps in reducing interference between the different paths in the splitter.

- 【Scalability】-They come in various split ratios, from 1x2 splitters to configurations like 1x32 or 1x64, providing flexibility and scalability in network design.

Applications

This is one of the primary applications of PLC splitters. They are used in PONs for distributing data to multiple endpoints. PONs are widely used in telecommunications for providing high-speed internet and television services. PLC splitters are essential in GPON (Gigabit PON), EPON (Ethernet PON), and other types of PON architectures.

In Fiber to the x (FTTx) systems, where “x” can be home (FTTH), curb (FTTC), building (FTTB), or other locations, PLC splitters are used to distribute the signal to multiple premises. They enable one single fiber coming from a central office to serve multiple homes or buildings.

In CATV (Cable Television) networks, PLC splitters are used to distribute TV signals from a single source to multiple subscribers, ensuring consistent signal strength and quality.

In LANs, especially those that require high bandwidth over a fiber optic backbone, PLC splitters can be used to distribute signals to different departments or units within an organization.

They are used in data centers and other data communication environments for routing optical signals to multiple locations or servers efficiently.

In WDM systems, which use multiple wavelengths of light on a single fiber, PLC splitters are used for evenly splitting signals across the different wavelengths.

Advantages vs Dis.

Advantages

Even Splitting –They provide very even splitting of optical signals, which is crucial for balanced data distribution in networks.

Low Insertion Loss –PLC splitters typically have lower insertion loss compared to other types of splitters, such as FBT (Fused Biconical Taper) splitters.

Wide Wavelength Range -PLC splitters can operate over a wide range of wavelengths, typically from 1260 to 1650 nm, making them suitable for various types of optical transmission systems.

Scalability -Available in various splitting ratios (like 1×8, 1×16, 1×32, 1×64), they offer flexibility in network design and scalability.

Disadvantages

Cost -Generally, PLC splitters are more expensive than FBT splitters, especially for lower split ratios.

Limited Splitting Ratios -While they offer various splitting options, the ratios are fixed. Once a PLC splitter is manufactured with a certain split ratio, it cannot be adjusted.

Signal Loss -Despite having low insertion loss, any form of splitting inevitably leads to some level of signal attenuation.

Inflexibility in Splitting Ratios -Unlike some other types of splitters that can offer variable splitting ratios, PLC splitters are fixed in their design, which might not be as adaptable for certain dynamic network requirements

How They Work

Input Signal: The process starts with an optical signal (like an internet signal) entering the PLC splitter through a single fiber.

Splitting the Signal: Inside the PLC splitter, this signal passes through a special optical chip. This chip is designed to split the incoming light into several paths, dividing it into equal or specific proportions. Think of it as a mirror maze where light bounces in different directions, but in a very controlled and precise manner.

Multiple Outputs: After the signal is split inside the chip, it exits the PLC splitter through multiple fibers. Each of these fibers carries a part of the original signal.

Uniform Distribution: The key feature of the PLC splitter is that it divides the signal uniformly. This means that each output fiber gets an equal share of the signal, ensuring that all users connected to these fibers receive a consistent signal strength.

How They Production

Assembling the PLC Chip

- The PLC chip is then assembled into a package that protects it and allows for fiber connections.

- Input and output fibers are aligned and attached to the chip. This alignment is crucial as it ensures the even distribution of light across all output fibers.

Packaging and Sealing

- The assembled PLC splitter is then packaged, often in a small, robust case that protects the internal components and provides points of attachment for the input and output fibers.

- Additional protective elements may be added to the package for thermal stability and to shield against environmental factors.

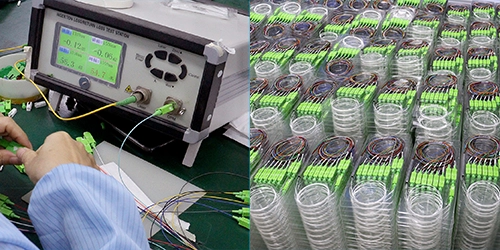

Testing and Quality Control

- Each splitter undergoes rigorous testing to ensure it performs as expected. This includes testing for insertion loss, uniformity of splitting, return loss, and environmental durability.

- Consistency and reliability are key, so quality control is a major part of the production process.

Component Fabrication

- The process begins with the fabrication of the various components of the connector. This typically includes the connector body, ferrule (a small, cylindrical component that holds the fiber), spring, and other mechanical parts.

- These components are often made from materials like plastic (for the body) and ceramic or metal (for the ferrule).

Final Packaging for Distribution

- Once they pass all tests, the PLC splitters are ready for final packaging and distribution.

- They are often packaged with protective elements to ensure safe transport to their final destination.

Optical Fiber Splitter supplier

Looking for Optical PLC Splitter for your Project?

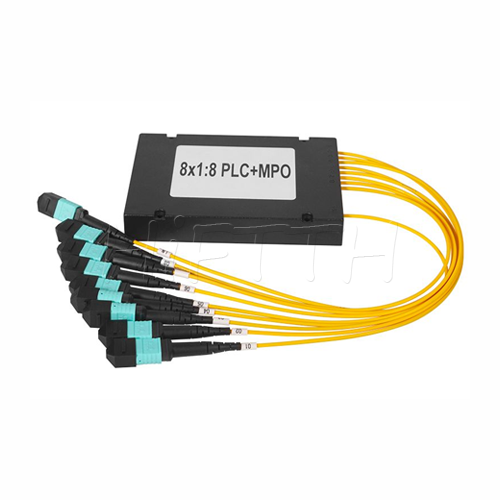

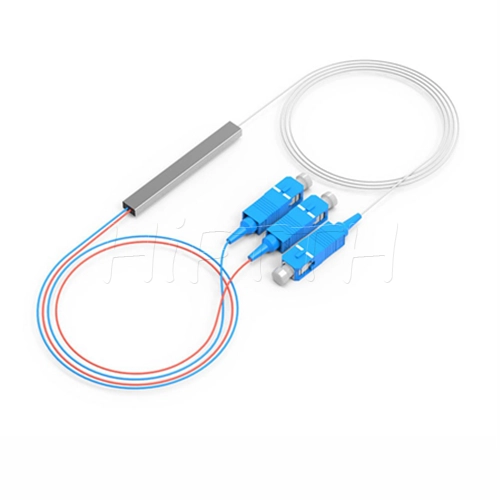

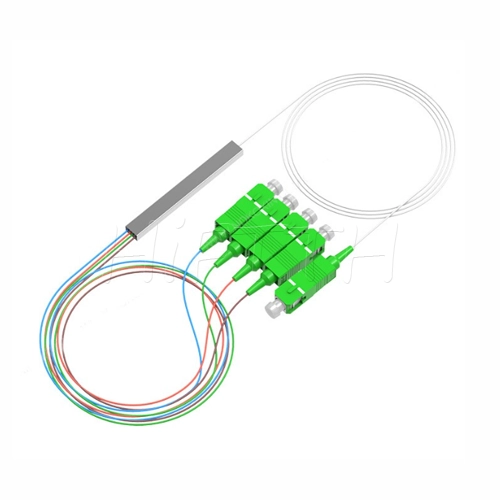

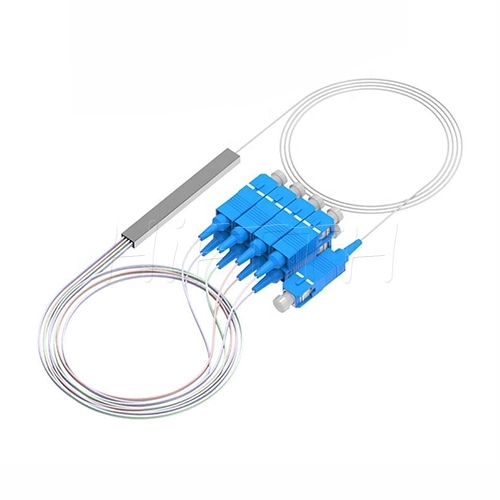

Products Shows

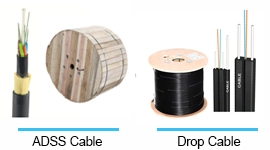

What we supply

Optical Fiber Splitter

They types are Rack-mounted splitter, Black box type splitter, Cassettes type splitter, Mini type splitter and LGX splitter.

The most used PLC splitter in ODN netowrk is mini type, also called steel tube type in Fiber Distribution Box or Fiber Optic Splice Closure.

The Black box type and cassette type are especially for Outdoor Fiber Distribution Cabinet.

Rack type for 19-inch Cabinet application.

More be coming

You Ask

We Answer

Need help?

FAQs

Does the product come with all necessary mounting accessories?

Optical splitters are generally divided into PLC (Planar Lightwave Circuit) splitters and FBT (Fused Biconical Taper) splitters.

What are the advantages of PLC splitters over FBT splitters?

PLC splitters offer higher reliability, better performance, and are suitable for applications requiring a large number of splits.

How do I determine the appropriate split ratio for my project?

The split ratio depends on the network design and the number of users to be served. Common ratios include 1:2, 1:4, 1:8, 1:16, and 1:32.

What factors influence the performance of optical fiber splitters?

Key factors include insertion loss, uniformity, polarization-dependent loss (PDL), and return loss.

What insertion loss should I expect for different split ratios?

Insertion loss increases with the split ratio has to contact with the PLC splitter factory to check it.

Are your splitters compatible with all fiber optic connectors?

Yes, we offer splitters with SC, LC, FC, and other connector options to suit your network requirements.

Can you customize the length of input and output tails for splitters?

Yes, input and output tail lengths can be customized based on your project needs.

What are the common packaging styles for optical fiber splitters?

Packaging styles include ABS box, LGX box, cassette type, and rack-mounted splitters.

What is the lead time for ordering optical fiber splitters?

Standard lead times range from 3-10 work days, depending on order volume and customization.

What should I consider when integrating splitters into an ODN network?

Pay attention to compatibility with existing equipment, insertion loss limits, and proper cable management.

What are the benefits of pre-installed splitters in enclosures?

Pre-installed splitters save installation time and reduce the risk of damage during handling.

Do you offer splitters for outdoor applications?

Can you customize the length of fiber pigtails for splitters?Yes, we provide splitters in weatherproof enclosures suitable for outdoor use.

How can I test the performance of an optical splitter?

Use an optical power meter and light source to measure insertion loss and uniformity.

Can I place a small trial order before bulk purchasing?

Yes, we support small trial orders to help you evaluate the product quality and performance.

What after-sales support do you provide for optical splitters?

We offer technical support, troubleshooting, and replacement services for any defective products.

How should I prepare for ordering optical fiber splitters?

Provide details on the split ratio, connector types, fiber type, and application scenario (for fiber distribution box / Joint Closure…).

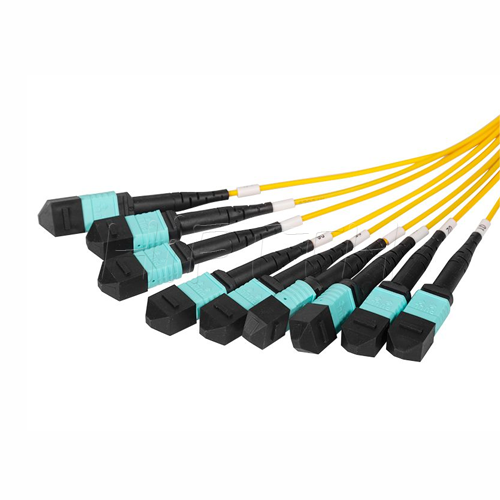

Related Products

Your ODN network product assistant