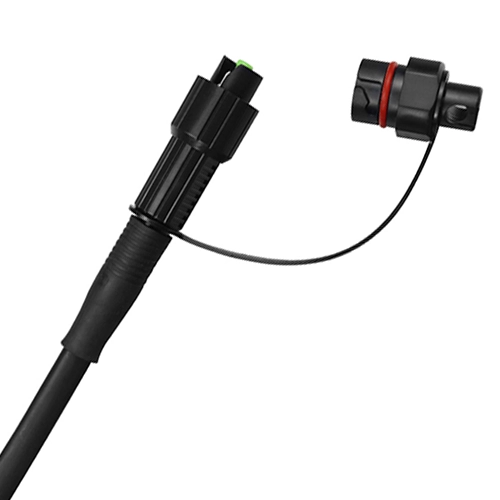

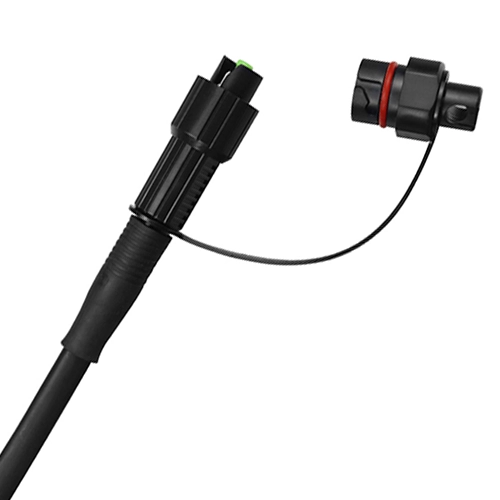

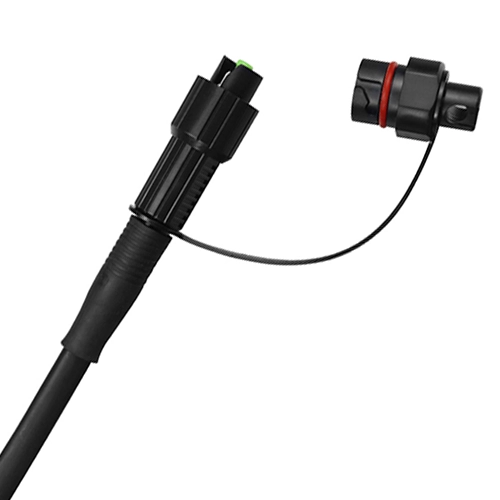

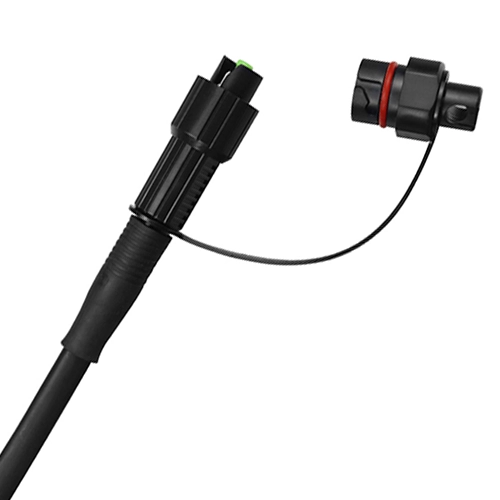

Pre terminated Fiber Optic Cable

Fiber Cable & Fiber Management

Pre terminated Fiber Optic Cable Box, PatchCord,Pigtail

Pre-terminated fiber optic cables simplify FTTH deployment with factory-assembled, ready-to-use solutions. Equipped with pre-installed connectors, they ensure quick, reliable connections for distribution and drop networks. Suitable for indoor and outdoor use, these cables support diverse architectures like GPON and ODN, streamlining high-speed broadband projects.

Pre-terminated cables reduce installation time and costs, enabling faster project completion. For ISPs, they ensure reliable, factory-tested performance with minimal maintenance. The plug-and-play design supports scalability and efficient deployment, cutting costs and improving service activation and customer satisfaction.

We do things differently

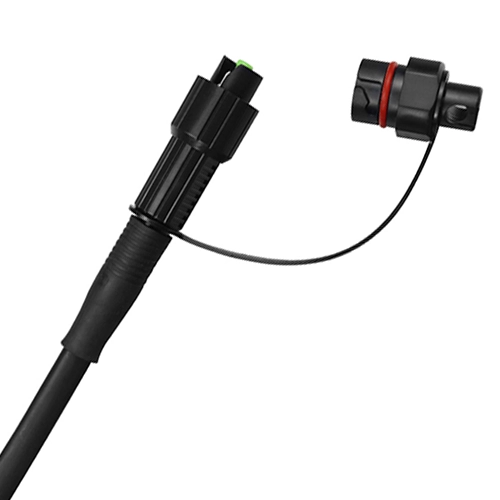

Plug-and-Play Design

Eliminates on-site splicing for faster deployment

Customizable Configurations

Cable lengths, connectors, and types meet requirment

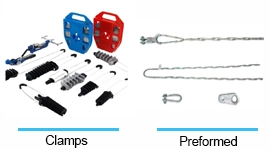

Weatherproof Protection

IP65 to IP68 ratings for outdoor durability

Wide Compatibility

Matching with Huawei, Corning, and Furukawa solution

Reduced Installation Time

Simplifies field setup with pre-connectorized cables.

Factory-Assembled Reliability

UV resistant

Flexible Order Quantities

Small and bulk orders both supported

Free Sample Availability

Free samples provided for testing and evaluation

Pre terminated Fiber Optic Cable supplier

Looking for Pre terminated Fiber Optic Cable for your Project?

Pre terminated Fiber Optic Cable different materials

Main structure differences

Pre terminated Fiber Optic Cable Products

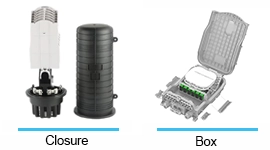

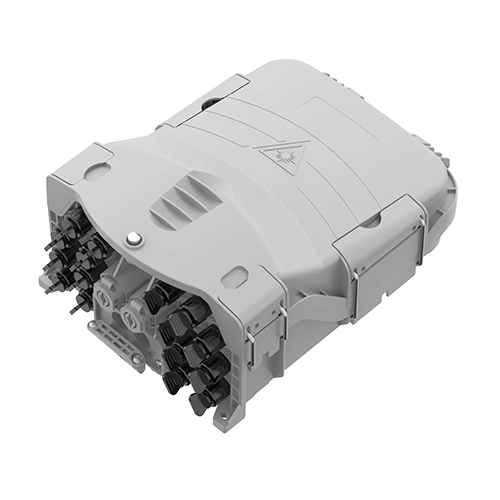

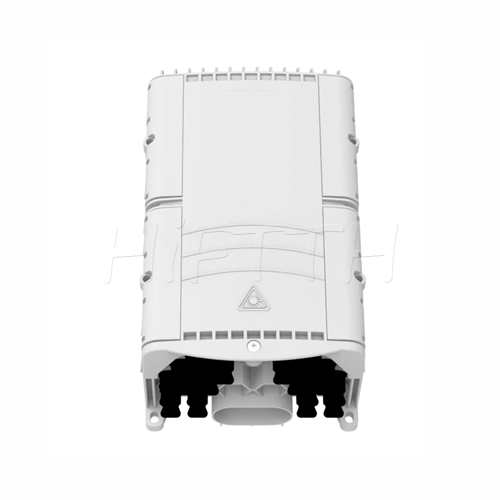

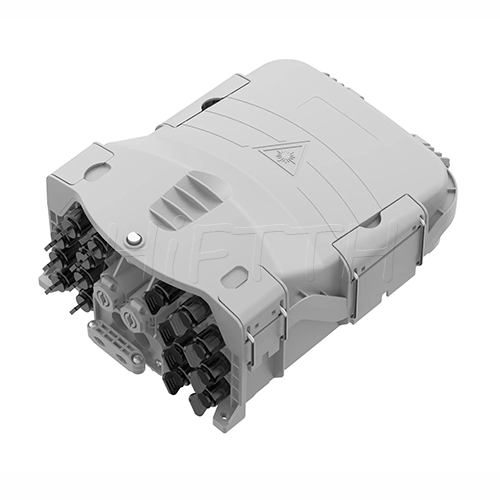

Pre terminated Fiber Optic Cable Box

HiFTTH’s Outdoor Fiber Optic Cable offers reliable connectivity with 100% quality assurance, competitive pricing, and free samples available. Built for durability in all outdoor environments.

Hub Box Sub Box and End Box

More be coming

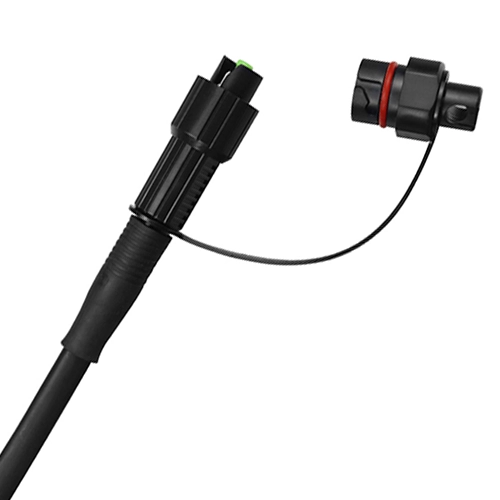

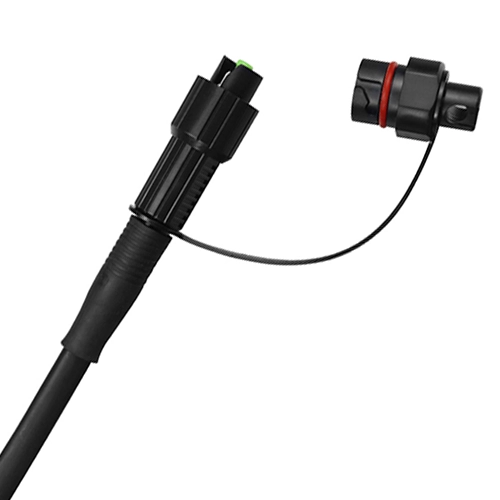

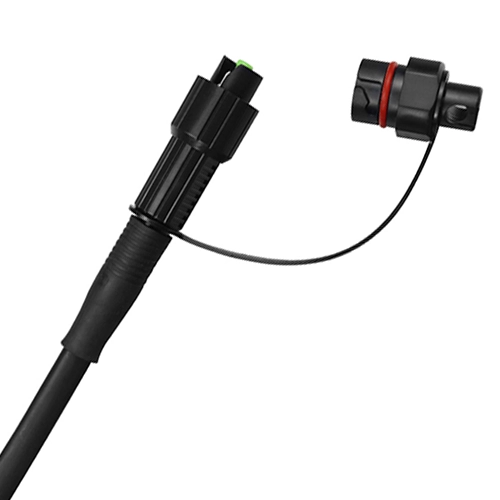

Pre terminated Fiber Assembly

More be coming

Pre terminated Fiber Optic Cable Typical application

ODN Application

What's Pre terminated fiber optic cable solution?

The Pre-terminated solution also called “pre-connected, pre-connectorized”. It is a cabling system where the connectors are factory-installed on the cable ends, so everything is ready to go when it arrives. You simply plug the cables into the network, with no need for field splicing or termination. This “plug-and-play” approach not only speeds up the installation process but also makes it much easier, especially for large projects. It eliminates the complexity of handling fiber in the field, reduces labor costs, and ensures high-quality, consistent connections right from the start.

Key points about Pre terminated fiber optic cable?

Factory-terminated

The connectors are professionally installed in a controlled environment, ensuring high quality and consistent performance.

Reduced installation time

No need for field termination, which saves time and labor costs during installation.

Improved reliability

Consistent quality control in the factory minimizes potential errors made during field termination.

Wide applications

Commonly used in fiber optic networks, particularly for FTTH (Fiber To The Home) deployments.

Does it meets with fiber splitting?

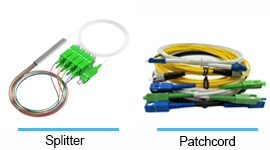

Built-in Splitters

Many pre-connectorized solutions include integrated splitters (e.g., 1:2, 1:4, 1:8, or even 1:16) within hubs.

These splitters allow signals to be distributed across multiple levels without additional splicing or field assembly.

Compatibility with Cascading

Pre-connectorized systems often support cascading designs, where multiple splitters are connected in series.

For example, you can use a 1:4 splitter in the primary distribution box and 1:8 splitters downstream for second-level splitting.

Support for Uneven Splitters

Pre-connectorized solutions can accommodate uneven splitters (e.g., 30/70 ratios), which are essential for optimizing signal distribution in networks with varying user density or distance requirements.

This flexibility allows efficient use of optical power, ensuring adequate signal strength across multi-level splitting setups.

Simplified Plug-and-Play for Multi-Level Splits

With connectors pre-installed, these solutions make it easy to implement multi-level splitting by simply connecting cables between splitters, hubs, and drop terminals.

Compared with traditional ODN, the Pre-terminated ODN solution stands out with following highlights.

- The fully sealed products can be less exposed to the risk of damage as we don't need to open the box repeatedly.

- The products adopt minimalist design. The box is easy to carry, and the pre-terminated fiber optic cable is plug and play.

- Fully pre-terminated design and minimalist installation greatly improve the efficiency.

- Pre terminated fiber optic cables are used for cascading, plug and play in the whole process, making the operation easier.

- After a fault occurs, the box or cable can be quickly replaced. The network fault recovery efficiency is increased by 90%.

- The whole construction process requires low skills and few tools. Therefore, the labor cost is lowered by 60%.

Need help?

FAQs

What is diffence with traditional cabling?

Traditional cabling requires on-site termination or splicing, while pre-connectorized solutions are plug-and-play, reducing time and errors.

What types of connectors are available?

Options include SC, LC, MPO, and custom connectors compatible with major systems like Huawei FastConnect, Corning OptiTap, and Fujikura Slim.

Are the cables customizable?

Yes, you can customize lengths, connector types, and jacket materials based on your project needs.

Do these solutions work in outdoor environments?

Yes, they are available with IP65 to IP68 waterproof ratings for harsh outdoor conditions.

How are repairs handled?

Damaged cables can be replaced or repaired using closures or spare lengths of pre-connectorized cables.

Do these solutions support future network upgrades?

Yes, they are modular and scalable, making them ideal for future expansions or upgrades.

Are they cost-effective compared to traditional methods?

While initial costs may be higher, they save significantly on labor, time, and maintenance, making them cost-effective overall.

Do you provide training or support for installation?

We offer installation guides, training, and after-sales support to ensure smooth deployment.

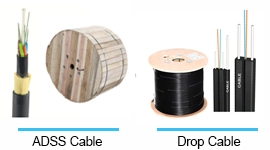

What cable types are available?

Options include flat drop cables, round cables, and indoor/outdoor drop cables.

How do they reduce installation time?

The plug-and-play design eliminates the need for field termination or splicing, speeding up deployment significantly.

Are these solutions suitable for FTTH projects?

Absolutely, they are ideal for FTTH as they simplify last-mile connectivity with reliable and fast installation.

What is the typical insertion loss for these cables?

Insertion loss varies by connector type but generally ranges between 0.1 and 0.3 dB for pre-terminated cables.

Are factory tests conducted on these products?

Yes, all pre-connectorized solutions undergo rigorous testing for insertion loss, return loss, and optical performance before shipment.

Are they compatible with existing network infrastructure?

Yes, they are designed to integrate seamlessly with legacy systems and major brands like Huawei, Corning, and Fujikura.

Can these solutions handle high user density?

Yes, they support large-scale deployments with multi-level splitters and scalable architecture.

Related Products

Your ODN network product assistant